Lean Principles: 5 Keys to Reducing Waste

“If you always do what you always did, you’ll always get what you’ve always got.”

Henry Ford, the founder of the Ford Motor Company.

What is Lean?

Lean is a method that is used for eliminating waste within a system while simultaneously maximizing productivity.

Origins of the Lean Principles

In 1913, Ford developed the assembly line method of manufacturing for the automobile in Highland Park, Michigan. This innovation radically transformed production to create goods quickly, efficiently, and in much larger quantities. Considered the “Father of Lean Manufacturing,” Ford implemented what would later become several principles, known as Lean.

In the 1950s, an engineer from rival Toyota, Taiichi Ohno, with other executives built upon Ford’s ideas. They made systematic changes to the automobile assembly process that resulted in the Lean Principles to allow for more flexibility in the types of cars produced without having significant efficiencies in the process. The improvements also emphasized the worker’s role in solving problems. Thus, management empowered workers at all levels to reduce waste and improve operations.

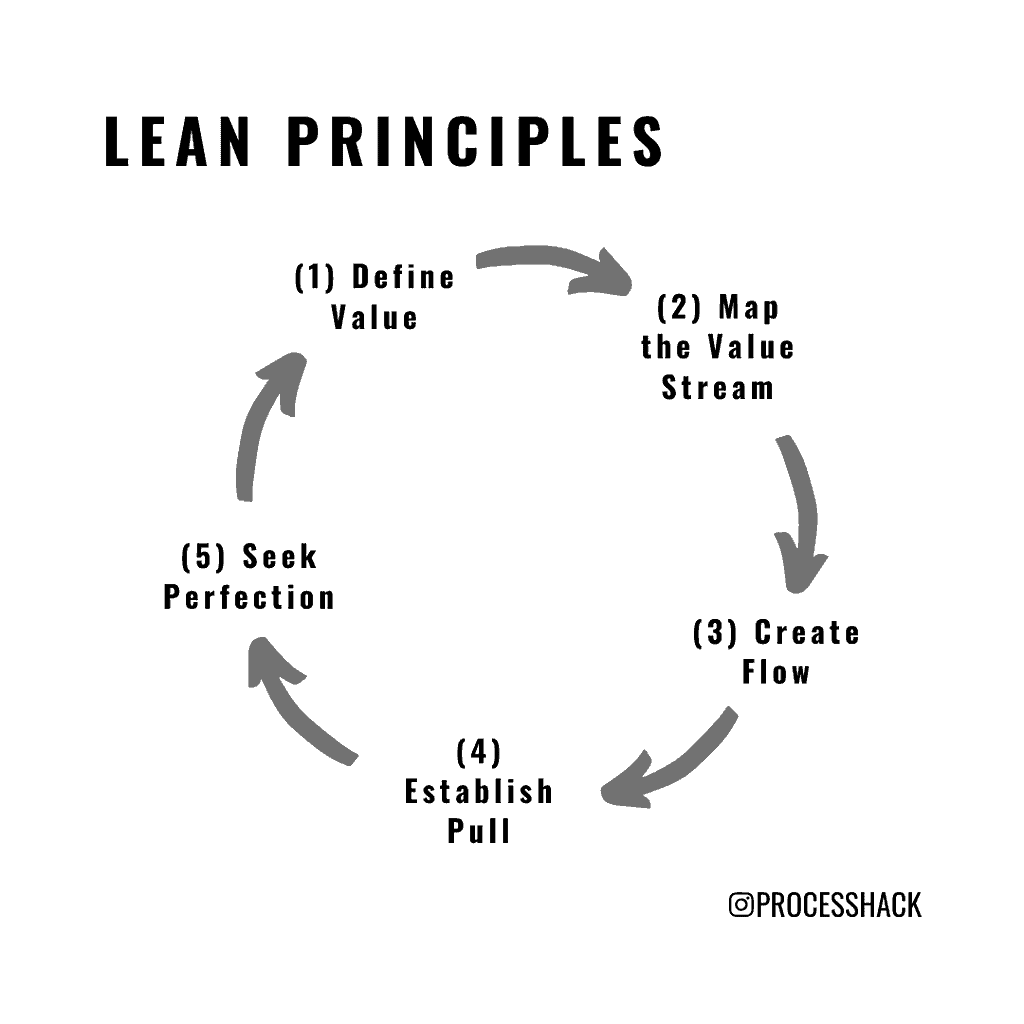

Principles of Lean

However, recently the methods have made its way into many types of businesses and management. The Lean principles derive from two high-level principles:

- Continuous Improvement: Anyone involved is empowered to improve the system or process regularly.

- Respect for People: Leaders and entrepreneurs should treat their customers and workers well as customers determine what gets produced, and workers have the immediate responsibility to deal with systemic issues.

In “The Machine That Changed the World,” Womack and Jones defined the five principles of Lean as follows: Define Value, Map the Value Stream, Create Flow, Use a Pull System, and Pursue Perfection.

Define Value

Value is defined by the customer’s requirements for a specific product or service.

When defined economically, value is how much money the customer is willing to pay for the product or service. However, value can be more than just a dollar value as you can still provide a ton of value without taking payment. For example, on YouTube, a viewer does not have to pay money to watch a video but will pay in their time and attention, which in turn generates ad revenue for the creator.

In lean principles, value is defined by figuring out the needs of the customer from their perspective. The goods and services provide a solution to the customer’s needs. Customer needs can be identified by having discussions, soliciting feedback, conducting focus groups, listening to social media, or doing market research. Thus, the unique value of the products or services needs to be determined.

Ask Yourself:

- What are the needs of your customers?

- Why do they need it?

- How does your product or service help the customer solve a problem in their life or work?

- Why will the customer choose your product or service over that of your competitors?

Map the Value Stream

Mapping the value stream is the tracing and examining the specific actions that are needed to produce a product or service.

The lean principle of mapping the value stream follows the process of created the product or service. One way to “map the value stream” is to create a process map, which is a tool that visually describes how value flows through the organization. The process map shows:

- The flow of materials and information,

- Tasks associated with a process,

- Required decisions along the way, and

- Relationships between the process steps.

Ask Yourself:

- What are the steps, decision points, and relationships in the process for your deliverable, product, or service?

- Who is responsible for the completion of each part of the process?

Example: Value Stream of Cake Shop

For example, the process map below shows the process for making a cake. It is assumed that all the ingredients are available, such that the process starts from when the order arrives to the delivery to the customer.

Create Flow

Flow is the continuous, progressive of adding value to your product or service.

In lean principles, value is added in the development of the product or service. Flow begins when there is a request from the customer and ends when the product or service is delivered to the customer. The process of value creation should ideally have no interruptions and the least amount of steps.

To create flow, you have to analyze the activities in your process based on value:

- Value Added: Activities that add something or make changes to a product or service for which the customer would be willing to pay.

- Required Non-Value Added: Activities that do not add value, but are necessary to make the product or service happen.

- Non-Value Added (Waste): Activities that do not add value and that the customer is not willing to pay.

We analyze the value stream to look for ways to improve efficiency and eliminate waste. Waste is the non-value added steps of the process. Waste is tough to recognize and comes in many forms: rework, over-production, periods of inactivity, underutilizing people, unnecessary motion, or excessive inventory.

Ask Yourself:

- What activities in your value stream are value-added?

- What activities in your value stream are non-value added?

- Are there ways to streamline the process?

- Can you eliminate the wasteful activities?

Establish Pull

A pull system is a system in which value is added when a downstream process requests it or a product or service is created when a customer orders it.

In contrast, the lean principle of the pull system is a predictive system. A schedule or forecast dictates the production of products or services.

We analyze the process by working backward from the end of the value stream. The customer has requirements for when they need the product or service delivered; thus, they “pull” the value out of the value stream when required. The usage of a pull system de-emphasizes the idea to be ready for the customer, which in turn reduces the investment of resources and space in materials, production, and storage.

Ask Yourself:

- When does the customer need our product or service?

- Can you meet the customer delivery date?

- How can you streamline your process such that delivery occurs as close to the delivery date?

Seek Perfection

Seeking perfection is striving to implement lean principles for continuous process improvement at all levels in an organization.

The last lean principle of seeking perfection is the most important, as it guides each member and the organization as a whole. The organization can empower its employees, who, in turn, seek to continually improve in their role while delivering products that satisfy the customer’s requirements.

Overall, this will lead to foster learning and constant growth for every employee and the company as a whole. For more on getting organized at work check out this blog post.

Next Steps

For additional help on getting leaner in your small business, check out Traction (book summary) by Gino Wickman.

If you have any further questions or need additional help, feel free to comment below or send me an email. Also, if you want more Process Hacker content, you should subscribe to our weekly newsletter on Productivity, Habits, and Resources.

I like that you spent time working through the visual models to represent the parts of a process that we might not see. When we receive the ‘cake’ or the end product, it’s easy to gloss over the details that brought it all together. In this post you spent time on value and also eliminating waste in the process. Thank you!